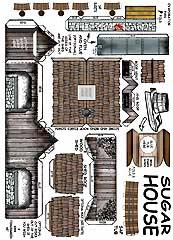

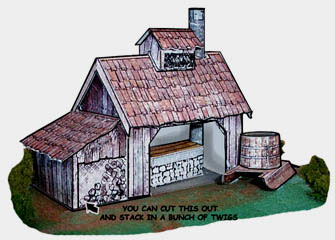

New England Maple Syrup Sugar House aka Sugar Barn

The New England tradition of boiling sap to make maple syrup and sugaroriginated with the region's Native American population. Today, NewEngland continues to produce some of the sweetest syrup and mapleproducts on the market. The maple sugaring season only lasts about fourto six weeks in Connecticut, from mid-February through late March whendays turn warm, nights remain cold, and the sap starts to flow.

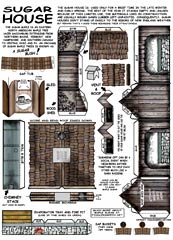

The New England tradition of boiling sap to make maple syrup and sugaroriginated with the region's Native American population. Today, NewEngland continues to produce some of the sweetest syrup and mapleproducts on the market. The maple sugaring season only lasts about fourto six weeks in Connecticut, from mid-February through late March whendays turn warm, nights remain cold, and the sap starts to flow.Sugarhouses were notbuilt until the 1800's; prior to that time sap for maple sugarwas boiled down in large iron kettles set in the open. The samekettles were used later in the season for boiling down applesfor apple butter. For sugar, sap was collected from the mapletrees in wooden troughs, then taken to a "sugar camp"where there were tents or rough shelters. Firewood had been stackedthere the year before, in preparation for the spring event inthe "sugar bush."

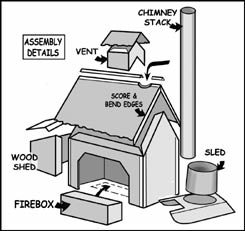

At the end of the 1700's, when tin evaporator pans and ovenswere introduced, a better shelter was needed, and the "sugarcabbin" was born. The cabbin was where one slept, and sincethe sap boied continuously for nearly a month-and needed constantwatching-

In the 18oo's, the cabin became the Sugar Barn with a hoodedopening in the roof peak and a shed for firewood. The roof wasusually shakes that were four-foot slabs of cedar or cedar bark.Most sugarhouses of Vermont and New Hampshire were a distancefrom the farm, the 'New York and Massachusetts houses were oftena part of the farm complex and were referred to as "suggarbarns.-

When you think of maple sugar you probably think of Vermont,which is not surprising when you consider that about half a milliongallons of maple syrup are produced here every year.

The process of boiling down the sap of the maple tree to extractits essence is called "sugaring off." As the sap isboiled, it is first reduced to syrup. If boiling continues, thesyrup is crystallized and it becomes maple sugar. Maple sugaris still made, but most of it is used for candy. Artifacts from the early days of maple sugaring are on displayat the New England Maple Museum, in Pittsford on U.S. 7, and atthe Maple Grove Maple Museum, in St. Johnsbury off 1-91.

In the old days, farmers collected sap in individual bucketshung from a tap in the tree. Buckets were decanted into a collectingtank on a sled or sledge and pulled by horses or oxen to thesugarhouse.Today,most operators run a plastic pipe from a number of treesto a collecting tank-or directly to the

In the old days, farmers collected sap in individual bucketshung from a tap in the tree. Buckets were decanted into a collectingtank on a sled or sledge and pulled by horses or oxen to thesugarhouse.Today,most operators run a plastic pipe from a number of treesto a collecting tank-or directly to the  sugarhouse. The modernmethod is more efficient but a lot less colorful.

sugarhouse. The modernmethod is more efficient but a lot less colorful.

At the sugarhouse, the sap is poured into large, flat evaporatingpans over a firebox fueled by wood or gas. As the sap boils downand thickens, the sweetsmelling steam rises and the liquid darkens.The syrup is filtered and graded. The lighter golden color isgraded higher and costs more than the darker, amber-colored syrup.It's a sugarhouse tradition to drop a dollop of hot syrup in thesnow to turn it into a sugary treat.

Many sugarhouses invite visitors to watch the aromatic processand sample the delicious finished product. A pamphlet called VermontMaple Sugarhouses Open to the Public lists producers, products,and availability for viewing. For a copy of the booklet, writeto the Vermont Department of Agriculture, 116 State Street, Montpelier,VT 05602, or call (802) 828-2416

Tradition has it that sugaring begins on Town MeetingDay, the first Tuesday in March. In fact, only a combination ofdaytime temperatures around 40' to 50'E and freezing nights willmake the sap run. This can be anytime between late February andlate March. The season ends three weeks to a month later, when the new leaves start using the sap for nourishment. Before youvisit any sugarhouse, be sure to call to make sure the sap is flowing.

Maply Syrup History Page

Where Did it Begin?

Maple syrup production goes so far back in American history

that no one actually knows how it started, Most historians accept

the idea that the Indians taught it to the early settlers. One

group, however, led by Carol L Mason from the University of Wisconsin

insists that the early French explorers or missionaries taught

the Indians. She says that the Indians didn't have the technology

or the "motivation" to go into production.

Maple syrup production goes so far back in American history

that no one actually knows how it started, Most historians accept

the idea that the Indians taught it to the early settlers. One

group, however, led by Carol L Mason from the University of Wisconsin

insists that the early French explorers or missionaries taught

the Indians. She says that the Indians didn't have the technology

or the "motivation" to go into production.

The American Indians, however, were accomplished woodsmen that used what they could from their surroundings. They were also very observant; they had to be to survive. They discovered herbs for flavoring food, healing, and poultices. They used tobacco in their peace pipes. At the end of winter, when all the stored grain and vegetables were gone. The Indians had plenty of motivation to find some variety in their diet and to use what they could to keep warm and survive. Once the Indians boiled the excess water out, the maple sugar that was left could be a source of energy and flavoring that they could store in cakes to use during the rest of the year.

Indian Names

Indians have names for the maple tree and its products. The Algonquin called maple sugar sinsibuckwud. The Ojibway said sheesheegummavvis, meaning"sap flows fast." The Cree called the maple tree sisibaskwattick. The Anishinabe of Minnesota do not know when they started making aninaatig ahfiwaagamizigan (maple syrup). For them, they've always made it.

The Legends

Indian tribes share various legends about how maple syrup was first made.

Nokomis

The Legend of Nokomis (the land), tells about Nokomis' granddaughter, Manabush tasting the drips after Nokomis had tapped the maple tree to collect syrup. Manabush felt that men would get lazy if all they had to do was to poke the tree, so she grabbed a bucket of water, climbed the maple tree and poured water into the center of the tree, diluting the sweet sap to only 1% to 2% sugar, She made it necessary for men to always work hard to get the syrup.

Glooskap

A similar legend. called the legend of Glooskap tells that

the Creator had long ago filled the maple trees with syrup that

flowed year-round. Glooskap known by different names to different

tribes (Gluscabi. Kuloscap, Manabozho, Odzihozo, or Djokabesh),

comes along to one of his People's villages. There are no cooking

fires and the gardens are overgrown. The children and dogs don't

run out to meet him. Glooskap finds the people in the maple grove,

lying down under the maple trees with their eyes closed,

letting the sweet sap drip into their open mouths. Dipping into

the nearby lake with a birchbark bucket he reache s up and fills the trees with water, thereby

diluting the sap. "Rise up, People. The trees are no longer

filled with the maple syrup the Creator gave to you. It is only

watery sap. Now you will have to hunt and fish and go back

to growing your corn, beans and squash."

s up and fills the trees with water, thereby

diluting the sap. "Rise up, People. The trees are no longer

filled with the maple syrup the Creator gave to you. It is only

watery sap. Now you will have to hunt and fish and go back

to growing your corn, beans and squash."

The Algonquin Chief

A different legend relates the experience of an Algonquin chief He struck a maple tree with his axe one day. His wife saw the tree wound dripping. She collected the sap in a wooden bucket and used it to boil the meat for supper. Both the chief and his wife were amazed at the sweetness of the meat that night.

Iriquois

An Iriquois legend simply says that one of their youths watched a squirrel run up a maple tree and bite off a twig. The squirrel licked the sap off the twig. When the Iriquois youth tried the same, he found the sap was sweet. Canadians have observed red squirrels running around from maple tree to maple tree nipping and creating deep wounds. After the wounds have exuded some sap, the squirrels return and eat the sugar crystals.

The Indians observed their surroundings. As forest dwellers, they had developed quite a sophisticated forest technology. If squirrels could do it, the Indians could definitely build on the squirrels' tactics.

Indian Sugar Production

For centuries Indians have tapped maples, gashed the bark under the tap in a V-shape and put out large birchbark bowls under the tap for collection. Earlier Indians would pour the sap into a hollowed out log or birchbark or clay kettle and drop hot rocks into the cooking vat until most of the water was boiled away. Later Indians would pour the sap into a clay or iron kettle held over a campfire.

Sugar Camps

Eastern woodland natives no matter how far they wandered in the winter for food could return to the maple groves, their ancestral "sugar camps." each spring and start the tapping process all over again.

Indian Sugar

Early White explorers wrote about the Indians having three types of maple sugar. "Grain Sugar" was a coarse granulated sugar similar to our brown sugar. "Cake Sugar- was poured into wooden molds to make blocks or rakes. "Wax Sugar" was extra thick sugar that was poured over snow, which is what we simply call "sugar on snow." Indeed, a few, very old maple trees show indications that the Indians were tapping long before the Europeans touched the American shoreline. Don Harlow of Putney, Vermont has an old maple that has tapping scars from waist high to about ten feet up.

Settlers Sugar Production

17th and l8th Century

When the Europeans came to Eastern Canada 300 years ago they

noticed the Indians used a dark sugar with a distinct taste-the

first kind of sugar produced in North America, The Indians taught

the settlers how to collect maple sap, and the settlers add ed their own technology

to the process. The Europeans used their augers to bore the tap

holes, devised wooden spiles (spouts), hung wooden buckets from

the spiles, and used their iron kettles to boil the sap.

ed their own technology

to the process. The Europeans used their augers to bore the tap

holes, devised wooden spiles (spouts), hung wooden buckets from

the spiles, and used their iron kettles to boil the sap.

At this time, maple sugar was a major source of high grade sugar for the French settlers. Imported white sugar was extremely expensive and hard to get. During these 200 years, Americans boiled virtually all of the sap they collected down into sugar. Maple syrup would not keep well.

19th Century

During the 1860s, a combination of developments pushed maple production to its peak. The Civil War soldiers desperately needed a source of good food that wouldn't spoil during shipment and storage. Soon, sheet metal began rolling out of American foundries, making all sorts of new applications possible. Among the first was the tin can. Not only did the can help the cause of the Civil War soldier, it was also a boon for sugarmakers who could now preserve maple syrup to use and sell year-round. Metal sap pails followed with lids to keep debris from falling into the sap. D. M. Cook used sheet metal to develop maple sap evaporation pans, About the same time, another inventor, Eli Mosher, devised a more durable metal spout.

By the 1900s, Cook and other sugarmakers had devised a flat-bottomed pan with baffles and channels in the bottom. With this method the heat from the fire could make contact with a larger volume of sap and boil the sap down much faster. These were the precursors of the modern evaporators.

20th Century

In 1959 Nelson Griggs invented plastic pipeline for use in maple sap collection. For twenty years or so developers struggled with various problems with the plastic tubing. By the time of the energy crisis in the 1970s, however, plastic tubing's problems had been straightened out.

Because of the oil crisis in the 70's, Canadian and United States agriculture departments focused on energy-efficient production of maple syrup. With the addition of vacuum pumps to the plastic tubing maple producers could now make even slow runs worth the effort to fire up the evaporators. The trees still had to be tapped and the pipeline strung, but the maple producer did not have to enlist an army of gatherers to trudge through the sugarbush and collect the sap from each bucket. The sap from each tap now runs by gravity through the plastic tubing downhill to a collecting tank, ready to be collected and taken to the sugarhouse.

In the 1970s, some sugarmakers starting using a process called reverse osmosis. This process separates water from water-soluble solids and can reduce the boiling process in half. Many sugarmakers say that reverse osmosis gives an off-taste to the syrup. They'd rather stay with the time-honored method of evaporating from start to finish. Maple Bush Farm does not use reverse osmosis.