Wind-Turbine - $$3.00

Windmills have been a part of man's life since the early days of civilization, making everyday life easier. Today's wind turbines, by harvesting the wind and generating electricity and with an almost zero carbon footprint are working toward solving the global warming problem. With wind turbines, as long as we have wind we'll have electricity!

Wind Turbine

Windmills have been a part of mans life since the early days of civilization, making everyday life easier. But today's modern day Wind Turbines are making millions of peoples life better by harvesting the wind and generating electricity. As long as we have wind we will have electricity!

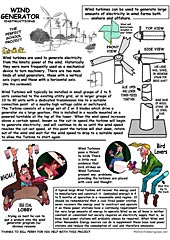

Wind Generator/Turbine

Vertical axis turbines operate in the airflow near the ground. |

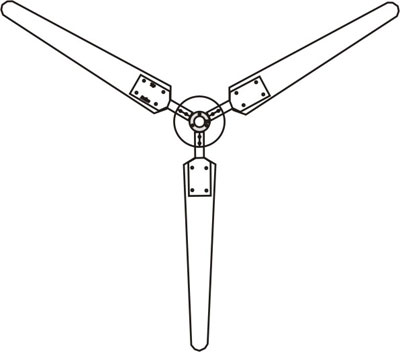

Horizontal Axis Turbines: Note: This model is a free download for a very limited time

The most common type of wind turbine is the

horizontal axis turbine. It has two or three blades

that spin around a horizontal shaft. The blades

are joined in the center by a hub. Together, the

blades and the hub are called the rotor. The rotor

is mounted on top of a tall tower, where the wind

blows freely without obstacles to slow it down.

The rotor is attached to a compartment called the

nacelle, which contains the gearbox, the

generator, and a computer. The computer tracks

the wind's speed and direction. When the wind's

direction changes, the computer activates a motor

to turn the nacelle, which moves the rotor into

the wind. The rotor will only spin when it is

facing into the wind.

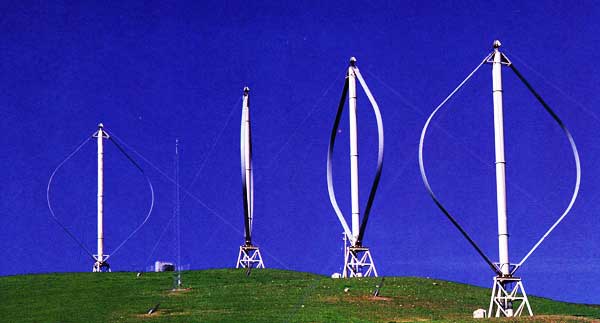

Vertical Axis Turbines:

|

A maintenance worker

checks the condition of this

wind turbine's blades at a

wind farm in England. |

Vertical axis turbines have two or three blades that spin around a vertical, or upright, shaft. The turbines do not need computers to move them into the wind, because the blades catch the wind from any direction. The gearbox is located near the ground at the base of the tower, which is thin and light. Vertical axis turbines produce less electricity than horizontal axis turbines because their blades are closer to the ground where the wind is slowed down by obstacles, such as trees.

Size and Power:

Wind turbines come in different sizes. Small

turbines have rotors from three to 50 feet in diameter. Their towers reach up to 130

feet high. They can generate up to 20

kilowatts of electricity and are used to

power homes, farm equipment, and small villages.

Large turbines are often called utility-scale

turbines because they generate enough power for

utilities, or electricity companies, to sell. Early

utility-scale turbines that generate between 50

and 100 kilowatts of electricity are being replaced

with larger turbines that generate thousands of

kilowatts. The largest turbines generate up to five

megawatts of electricity, which is enough

energy to power 5,000 homes! Today, the rotors

and towers of utility-scale turbines range from

164 feet to 795 feet in length.

Safety Measures:

The faster the wind blows, the faster a wind

turbine's blades spin. Strong winds can make the

blades spin so fast that the turbine vibrates,

which can damage the blades, or cause them to

snap off. To prevent these accidents, turbines

are designed to reach a maximum speed,

which varies according to the turbine's size.

When a utility - scale turbine reaches its

maximum speed, its computer tilts the

blades to catch less wind to slow them.

This is called furling. Computers also

activate brakes on the rotor to slow

the blades. The rotors of most small

turbines are attached to the towers

on a hinge. When the turbine

reaches its maximum speed,

the rotor tilts on the hinges

out of the wind to slow the

blades down.

Wind Farms:

Wind Farms:

Wind farms, also called wind power plants, are

made up of several wind turbines grouped

together to produce large amounts of electricity.

Siting:

Choosing a location for a wind farm is called

siting. It is very important that the site has

strong, steady winds. Developers, or the people

building a wind farm, study and measure the

wind of an area before building a wind farm

there. The best sites for wind farms are the coasts

of large lakes and oceans, hilltops, open plains,

and mountain passes. Developers must determine

whether or not it is possible to connect to the

power grid from the site. What impact the wind

farm will have on wildlife is also considered.

They need to get permission from the community

or government before the wind farm can be built.

Arranging Turbines:

Once a site for a wind farm is chosen, developers

plan the placement of the wind turbines. The

turbines are usually arranged in rows facing in the

direction of the prevailing wind. Wind turbines

are usually spaced about five to nine times the

diameter of their rotors apart. Turbines with

rotors 165 feet across are spaced 825

to 1,485 feet apart. If

turbines are placed too close together, they block

one another's wind. Placing the turbines too far

apart wastes space on the wind farm.

From Farm to Grid:

The electricity that wind farms generate is sent

to the power grid, which delivers electricity to

homes, schools, factories, and other buildings.

The electricity flows along cables from the wind

farm to a network of underground wires, which

lead to a substation. The substation has a

transformer, which is a device that increases the

electricity to a very high voltage, or force. High-

voltage electricity travels more efficiently along

power lines, so less electricity gets lost along the

way. The high-voltage electricity flows from the

substation to power lines throughout the grid.

Substations and transformers

at the other end of the

power lines transform the

electricity to lower

voltages before it flows

into homes and other

buildings. The voltage

must be lowered so that

appliances and other electric

devices can run on it safely.

Harvesting Wind:

In many parts of North America,

farmers and ranchers are increasing

their earnings by farming the wind.

Developers build wind farms on

farmland, and pay the farmers and

ranchers rent or a share of the

wind farm's earnings. The turbines

do not interfere with ranching or

farming. Cattle and sheep graze

under the turbines, and farmers can

plant crops right up close to the

base of each turbine.

Powering Schools:

In 1993, Spirit Lake Elementary School, in Spirit Lake, Iowa, became

the first school in the United States to be powered by wind. The

school's electricity is produced by u 250 kW wind turbine located

behind the playground. In 2001, a second turbine was built to power

Spirit Lake's middle school, high school,

bus shelter, and football stadium. This

turbine sends electricity directly to

l.

the power grid. The utility keeps

track of how much electricity the

turbine sends to the power grid

and how much electricity the

schools use from the grid. If the

turbine produces more electricity

than the schools use, the utility pays

the schools for the electricity.

Offshore Wind Farms:

Offshore wind farms are located in the shallow

waters of coastlines. There are several reasons for

putting wind turbines offshore. Many small

European countries, such as Denmark, Sweden,

and Holland, are running out of space for wind

farms on land. Winds blow stronger and more

steadily across water than they do over land,

because they encounter fewer obstacles. This

means there is more energy offshore for turbines

to harness. Offshore turbines produce about 50

percent more electricity than turbines on land.

Underwater construction for offshore wind farms

is difficult and expensive. The bottoms of the

towers and the cables that carry electricity from

the turbines must be buried deep into the seabed.

It is also more difficult to maintain and repair

offshore turbines.

Wind Turbines- over view:

A wind turbine is a machine that converts the wind's kinetic energy into rotary mechanical energy, which is then used to do work. In more advanced models, the rotational energy is converted into electricity, the most versatile form of energy, by using a generator.

A wind turbine is a machine that converts the wind's kinetic energy into rotary mechanical energy, which is then used to do work. In more advanced models, the rotational energy is converted into electricity, the most versatile form of energy, by using a generator.

For thousands of years people have used windmills to pump water or grind grain. Even into the twentieth century tall, slender, multi-vaned wind turbines made entirely of metal were used in American homes and ranches to pump water into the house's plumbing system or into the cattle's watering trough. After World War I, work was begun to develop wind turbines that could produce electricity. Marcellus Jacobs invented a prototype in 1927 that could provide power for a radio and a few lamps but little else. When demand for electricity increased later, Jacobs's small, inadequate wind turbines fell out of use.

The first large-scale wind turbine built in the United States was conceived by Palmer Cosslett Putnam in 1934; he completed it in 1941. The machine was huge. The tower was 36.6 yards high, and its two stainless steel blades had diameters of 58 yards. Putnam's wind turbine could produce 1,250 kilowatts of electricity, or enough to meet the needs of a small town. It was, however, abandoned in 1945 because of mechanical failure.

With the 1970s oil embargo, the United States began once more to consider the feasibility of producing cheap electricity from wind turbines. In 1975 the prototype Mod-O was in operation. This was a 100 kilowatt turbine with two 21-yard blades. More prototypes followed (Mod-OA, Mod-1, Mod-2, etc.), each larger and more powerful than the one before. Currently, the United States Department of Energy is aiming to go beyond 3,200 kilowatts per machine.

Many different models of wind turbines exist, the most striking being the vertical-axis Darrieus, which is shaped like an egg beater. The model most supported by commercial manufacturers, however, is a horizontal-axis turbine, with a capacity of around 100 kilowatts and three blades not more than 33 yards in length. Wind turbines with three blades spin more smoothly and are easier to balance than those with two blades. Also, while larger wind turbines produce more energy, the smaller models are less likely to undergo major mechanical failure, and thus are more economical to maintain.

Wind farms have sprung up all over the United States, most notably in California. Wind farms are huge arrays of wind turbines set in areas of favorable wind production. The great number of interconnected wind turbines is necessary in order to produce enough electricity to meet the needs of a sizable population. Currently, 17,000 wind turbines on wind farms owned by several wind energy companies produce 3.7 billion kilowatt-hours of electricity annually, enough to meet the energy needs of 500,000 homes.

Raw Materials:

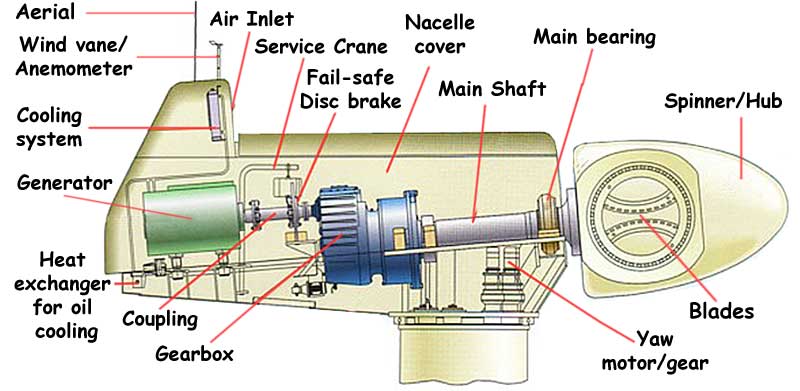

A wind turbine consists of three basic parts: the tower, the nacelle, and the rotor blades. The tower is either a steel lattice tower similar to electrical towers or a steel tubular tower with an inside ladder to the nacelle. Most towers do not have guys, which are cables used for support, and most are made of steel that has been coated with a zinc alloy for protection, though some are painted instead. The tower of a typical American-made turbine is approximately 80 feet tall and weighs about 19,000 pounds.

The nacelle is a strong, hollow shell that contains the inner workings of the wind turbine. Usually made of fiberglass, the nacelle contains the main drive shaft and the gearbox. It also contains the blade pitch control, a hydraulic system that controls the angle of the blades, and the yaw drive, which controls the position of the turbine relative to the wind. The generator and electronic controls are standard equipment whose main components are steel and copper. A typical nacelle for a current turbine weighs approximately 22,000 pounds.

The most diverse use of materials and the most experimentation with new materials occur with the blades. Although the most dominant material used for the blades in commercial wind turbines is fiberglass with a hollow core, other materials in use include lightweight woods and aluminum. Wooden blades are solid, but most blades consist of a skin surrounding a core that is either hollow or filled with a lightweight substance such as plastic foam or honeycomb, or balsa wood. A typical fiberglass blade is about 15 meters in length and weighs approximately 2,500 pounds.

Wind turbines also include a utility box, which converts the wind energy into electricity and which is located at the base of the tower. Various cables connect the utility box to the nacelle, while others connect the whole turbine to nearby turbines and to a transformer.

The Manufacturing

Process:

Before consideration can be given to the construction of individual wind turbines, manufacturers must determine a proper area for the siting of wind farms. Winds must be consistent, and their speed must be regularly over 15.5 miles per hour (25 kilometers per hour). If the winds are stronger during certain seasons, it is preferred that they be greatest during periods of maximum electricity use. In California's Altamont Pass, for instance, site of the world's largest wind farm, wind speed peaks in the summer when demand is high. In some areas of New England where wind farms are being considered, winds are strongest in the winter, when the need for heating increases the consumption of electrical power. Wind farms work best in open areas of slightly rolling land surrounded by mountains. These areas are preferred because the wind turbines can be placed on ridges and remain unobstructed by trees and buildings, and the mountains concentrate the air flow, creating a natural wind tunnel of stronger, faster winds. Wind farms must also be placed near utility lines to facilitate the transfer of the electricity to the local power plant.

Preparing the Site:

Preparing the Site:

Wherever a wind farm is to be built, the roads are cut to make way for transporting parts. At each wind turbine location, the land is graded and the pad area is leveled. A concrete foundation is then laid into the ground, followed by the installation of the underground cables. These cables connect the wind turbines to each other in series, and also connect all of them to the remote control center, where the wind farm is monitored and the electricity is sent to the power company.

Erecting the Tower:

Although the tower's steel parts are manufactured off site in a factory, they are usually assembled on site. The parts are bolted together before erection, and the tower is kept horizontal until placement. A crane lifts the tower into position, all bolts are tightened, and stability is tested upon completion.

Nacelle

The fiberglass nacelle, like the tower, is manufactured off site in a factory. Unlike the tower, however, it is also put together in the factory. Its inner workings—main drive shaft, gearbox, and blade pitch and yaw controls—are assembled and then mounted onto a base frame. The nacelle is then bolted around the equipment. At the site, the nacelle is lifted onto the completed tower and bolted into place.

Rotary Blades:

Aluminum blades are created by bolting sheets of aluminum together, while wooden blades are carved to form an aerodynamic propeller similar in cross-section to an airplane wing. Many blades are molded with fiberglass.

By far the greatest number of blades, however, are formed from fiberglass. The manufacture of fiberglass is a painstaking operation. First, a mold that is in two halves like a clam shell, yet shaped like a blade, is prepared. Next, a fiberglass-resin composite mixture is applied to the inner surfaces of the mold, which is then closed. The fiberglass mixture must then dry for several hours; while it does, an air-filled bladder within the mold helps the blade keep its shape. After the fiberglass is dry, the mold is then opened and the bladder is removed. Final preparation of the blade involves cleaning, sanding, sealing the two halves, and painting.

The blades are usually bolted onto the nacelle after it has been placed onto the tower. Because assembly is easier to accomplish on the ground, occasionally a three-pronged blade has two blades bolted onto the nacelle before i t is lifted, and the third blade is bolted on after the nacelle is in place.

t is lifted, and the third blade is bolted on after the nacelle is in place.

Installation of Control Systems:

The utility box for each wind turbine and the electrical communication system for the wind farm is installed simultaneously with the placement of the nacelle and blades. Cables run from the nacelle to the utility box and fromthe utility box to the remote control center.

Quality Control:

Unlike most manufacturing processes, production of wind turbines involves very little concern with quality control. Because mass production of wind turbines is fairly new, no standards have been set. Efforts are now being made in this area on the part of both the government and manufacturers.

While wind turbines on duty are counted on to work 90 percent of the time, many structural flaws are still encountered, particularly with the blades. Cracks sometimes appear soon after manufacture. Mechanical failure because of alignment and assembly errors is common. Electrical sensors frequently fail because of power surges. Non-hydraulic brakes tend to be reliable, but hydraulic braking systems often cause problems. Plans are being developed to use existing technology to solve these difficulties.

Wind turbines do have regular maintenance schedules in order to minimize failure. Every three months they undergo inspection, and every six months a major maintenance checkup is scheduled. This usually involves lubricating the moving parts and checking the oil level in the gearbox. It is also possible for a worker to test the electrical system on site and note any problems with the generator or hookups.

Environmental Benefits

and Drawbacks:

Environmental Benefits

and Drawbacks:

A wind turbine that produces electricity from inexhaustible winds creates no pollution. By comparison, coal, oil, and natural gas produce one to two pounds of carbon dioxide (an emission that contributes to the greenhouse effect and global warming) per kilowatt-hour produced. When wind energy is used for electrical needs, dependence on fossil fuels for this purpose is reduced. The current annual production of electricity by wind turbines (3.7 billion kilowatt-hours) is equivalent to four million barrels of oil or one million tons of coal.

Wind turbines are not completely free of environmental drawbacks. Many people consider them to be unaesthetic, especially when huge wind farms are built near pristine wilderness areas. Bird kills have been documented, and the whirring blades do produce quite a bit of noise. Efforts to reduce these effects include selecting sites that do not coincide with wilderness areas or bird migration routes and researching ways to reduce noise.

The Future:

Research is now being done to increase the knowledge of wind resources. This involves the testing of more and more areas for the possibility of placing wind farms where the wind is reliable and strong. Plans are in effect to increase the life span of the machine from five years to 20 to 30 years, improve the efficiency of the blades, provide better controls, develop drive trains that last longer, and allow for better surge protection and grounding. The United States Department of Energy has recently set up a schedule to implement the latest research in order to build wind turbines with a higher efficiency rating than is now possible. (The efficiency of an ideal wind turbine is 59.3 percent. That is, 59.3 percent of the wind's energy can be captured. Turbines in actual use are about 30 percent efficient.) The United States Department of Energy has also contracted with three corporations to research ways to reduce mechanical failure. This project began in the spring of 1992 and will extend to the end of the century.

Wind turbines will become more prevalent in upcoming years. The largest manufacturer of wind turbines in the world, U.S. Windpower, plans to expand from 420 megawatt capacity (4,200 machines) to 800 megawatts (8,000 machines) by 1995. They plan to have 2,000 megawatts (20,000 machines) by the year 2000. Other wind turbine manufacturers also plan to increase the numbers produced. International committees composed of several industrialized nations have formed to discuss the potential of wind turbines. Efforts are also being made to provide developing countries with small wind turbines similar to those Marcellus Jacobs built in the 1920s. Denmark, which already produces 70 percent to 80 percent of Europe's wind power, is developing plans to expand manufacture of wind turbines. The turn of the century should see wind turbines that are properly placed, efficient, durable, and numerous.

Global Warming:

The growing concern about Global Warming and Greenhouse gas production has lead Governments worldwide to consider clean alternatives to Coal and Diesel for the production of electricity. Australians are the worst greenhouse gas emitters in the world. 43% of Victoria’s emissions are produced by the burning of brown coal for the production of electricity. The Australian Government has set a requirement that by 2010 Renewable Energy will provide 9500 gigawatt hours of electricity per year. This equates to approximately 4000 megawatts of installed capacity of Renewable Energy sources or the equivalent of two Loy Yang A power stations. Renewable Energy is clean energy and is as close to greenhouse gas neutral as it is possible to achieve.

Why Wind

What about Solar Power, Hydropower and Biomass:

• Solar electricity is currently very expensive (about $13 per watt installed) And there is no sign of solar getting any cheaper, in fact all suppliers of solar panels have recently increased their prices. While well suited to applications such as remote homes, remote communications and navigation aids for instance, the cost and payback period for grid connected solar is not viable without government grants.

• Solar electricity is currently very expensive (about $13 per watt installed) And there is no sign of solar getting any cheaper, in fact all suppliers of solar panels have recently increased their prices. While well suited to applications such as remote homes, remote communications and navigation aids for instance, the cost and payback period for grid connected solar is not viable without government grants.

• Hydro electricity is by far the most cost effective form of Renewable Energy, however Government policy is that no new dams will be built for Hydro, so the only opportunities are to install Hydro Turbines on existing infrastructure or dams , these opportunities are few and far between and will not be enough to meet the requirement.

• Biomass covers a wide range of energy sources and technologies, from burning household rubbish to make steam for the generation of electricity to growing crops to burn or to produce oil (i.e. Canola oil) which when treated can be used as a Diesel substitute. The economies of these technologies have yet to be proven.

Wind Energy Is Proven Technology:

Some European countries have had Wind Turbines in operation for over 20 years. Wind Energy production costs in Europe are now competing with coal fired power stations. Since 1990 the Wind Energy Industry has been the fastest growing sector of the power generation industry and continues to be so. Large scale Wind Turbines can be installed for about $2.00 per watt or about two million dollars per megawatt. A typical Wind Farm will use about 1% of the area where it is constructed leaving the rest for normal farming or grazing practices. Wind Turbines have a designed working life of 20 to 25 years and require very little maintenance during this time.

Wind Turbines:

Wind Turbines will typically be installed in small groups of 2 to 5 units connected to the existing utility grid, or in larger groups of 10 to 30 units with a dedicated transmission line to a suitable connection point at a nearby high voltage cable or switchyard. The Turbine consists of a large set of 3 blades which drive a generator via a large gearbox, this is installed in a nacelle which is mounted on a powered turntable at the top of a tall tower. When the wind speed increases above a certain speed , known as the cut in speed typically about 3 to 4m/s (meters per second) The Turbine will begin to generate electricity, and will continue to do so until the wind speed reaches the cut out speed, (about 25m/s) at this point the turbine will shut down, rotate out of the wind and wait for the wind speed to drop to a suitable speed to allow the Turbine to start again. The Turbine will have an optimum operating wind speed at which maximum output will be achieved, this is typically about 13 to 16m/s During operation the generator ensures that the blades maintain a constant speed of about 20 revolutions per minute, which the gearbox transforms into 1500 revolutions per minute. Higher wind loads acting on the blades result in increased power production but not a higher number of revolutions per minute.

How Big:

Wind Turbines are big a typical Turbine of the size to be used in Australia will be installed on a tower which is between 150 feet and 240 feet tall. The rotor diameter (blade span) will be between 150 feet and 240 feet. Turbine towers are constructed from rolled steel plate and are normally about 12 to 15 feet diameter at the base and about 6 to 9 feet diameter at the top. Turbines are installed on concrete foundations that are buried well below ground level with a pedestal to mount the tower on so the landholder can work the land right up to the base of the tower.

Noise Issues:

Wind turbines are not noisy ; a typical 1.5 megawatt (15,000,000 watt) Turbine, similar to the Turbines installed at Codrington and Toora will produce 45dB(A)

or less at 300 meters. This noise level is about the same noise level you will hear sitting in your kitchen listening to your fridge.The average noise level in a typical home is 50dB(A). However this is only the noise produced by the Turbine, the natural wind rush noise is heard as well and this is normally about 40dB(A) so the end result at a typical exclusion distance of 300 to 400 meters is that the Turbines are almost inaudible. Some Turbines produce up to 100dB(A) but this is measured at the gearbox at the top of the tower. The fact is that with the turbine running at its rated speed a normal conversation can held at the base of the tower. This can be proven quite easily by visiting one of the existing Wind Farms and hearing for yourself.

Embodied Energy:

Germany is one of the largest users of Wind Energy with 6113 megawatts of Wind Turbines installed, this is assisting the German Government to close its nuclear power stations. The Danish Government has determined that Wind Energy will provide 50% of the countries energy requirements by 2030; this means a 50% reduction in greenhouse emissions if this Energy was sourced from coal power stations. In Victoria the brown coal power stations of the LaTrobe Valley produce almost 10% of Australia’s CO2 emissions or 2kg of CO2 for every kilowatt hour of electricity produced.

Birds:

Wind Turbines pose little threat to birds, there is little real evidence here or overseas that bird strikes on Wind Turbines present any real problem providing the Turbines are placed with care and thought. The Americans who in the 80’s built several Wind Farms in California have largely caused the concern regarding bird strikes. These Wind Farms were built without consideration of aesthetic or environmental issues and caused many problems including bird kills. The Wind industry worldwide has learnt from this experience and no reputable Wind Farm Developer would consider the wall to wall Wind Turbine option. It is unlikely that any Council or State Government would allow this type of development. If we are really concerned about the plight of Birds perhaps we should be looking at Cats, Cars and power lines.

Capacity Factor:

Capacity factor, sometimes called load factor is the amount of time an energy production source is able to produce electricity. A coal power station will have a capacity factor of 65 to 85% that is, it will be able to produce output for 65 to 85% of the time, it will be out of action the rest of the time due to maintenance, labor strikes, breakdowns etc. A typical Wind Turbine will have a capacity factor of 25 to 40% depending on the available wind resource. Currently in Australia a Wind Farm will need a capacity factor of 32% or better to be viable.

What Does Having Wind Turbines On Your Property Mean To You:

For some people the greatest benefit of having Wind Turbines on their property will be the contribution to reducing greenhouse gas emissions and for others it will be the guaranteed income for the life of the Turbines (20 to 25 years) Currently you could expect up to $3000 per megawatt installed (or part there off ) per annum with no outgoings at all. The process of establishing Wind Turbines can be a drawn out affair and may take 2 to 3 years from first contact to construction and commissioning.

|

|

|

These cutouts, created by our good pal, Dereck Carter, are included with your FREE Wind Generator cardmodel. Great fun and a great way to make an eco-statement. Other mills from Fiddlersgreen:

|

|

||

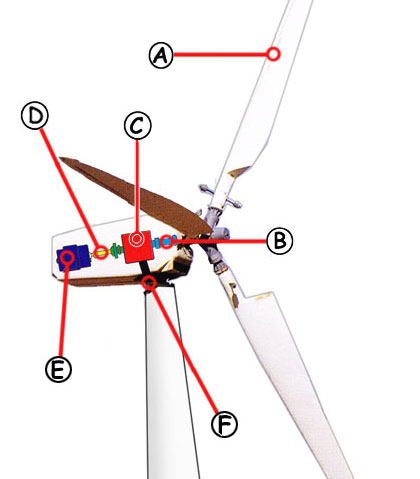

| A: The wind blows against the blades and makes them turn creating massive torque | B: The blades are connected to a main shaft, or pole. As the blades turn, the main shaft turns. | C: The main shaft is connected to a gearbox. Inside the gearbox, large gears slowly turn, which makes smaller gears turn quickly. |

| D: The gears turn another shaft, called the high-speed shaft, very quickly. | E: The high-speed shaft is connected to a generator, which is made up of magnets inside coils of copper wire. | F: Thick cables carry the electric current, or electricity, out of the generating unit. |

|

Fenner, NY: Marvin DeKing already was up and awake between 3 and 4 a.m. when he heard a loud bang. It sounded like thunder and lightning, said DeKing, in this rural town five miles northeast of Cazenovia. But it wasn't until daylight that DeKing learned what had caused the noise - The 187 ton windmill across the road from his house had fallen over and lay sprawled in the cornfield in which it had stood. |