Gloster-E28 - $$5.50

The first British Jet aircraft powered by the new fangled Whittle W1 centrifugal engine. It flew brilliantly but the Germans had already been there-done that but a year and a half earlier. The first German jet, the Heinkel He-178 is available. Tthe American P-59 will join the Jets Collection ASAP.

Gloster E28/30 Whittle, Pioneer First British Jet Plane

Summary of the Gloster E.28 Aircraft

The Gloster E.28/39, also known as the Gloster Whittle, was an experimental British aircraft designed and built by the Gloster Aircraft Company in the late 1930s. It was the first aircraft to fly using a jet engine, and it achieved this milestone on May 15, 1941.

The E.28/39 was developed in response to a specification issued by the British Air Ministry in 1937, which called for a single-seat, high-speed interceptor powered by a jet engine. The project was led by Gloster's chief designer, George Carter, and the jet engine was developed by Sir Frank Whittle.

The E.28/39 made its maiden flight on May 15, 1941, with Gloster's chief test pilot, Flight Lieutenant Philip Lucas, at the controls. The aircraft reached a top speed of around 400 mph (640 km/h) and performed well in flight tests. However, it was not developed further due to the priority given to other aircraft projects during World War II.

Despite its limited role in the war, the E.28/39 played an important role in the development of jet aviation. It demonstrated the viability of the jet engine as a powerplant for aircraft and laid the foundation for the development of many other jet-powered aircraft that followed.

(This information was written by ChatGPT 2022-12-17).

The Birth of the Jet

On 8th April 1941 a top-secret event which was to revolutionize world aviation took place at Brockworth in the County of Gloucestershire.

After initial taxi trials the pilot P.E.G. (Phillip Edward Gerald) Sayer pushed the throttle lever forward until the engine indicator read 16,000 rpm and the Gloster E28/39, Britain's first jet aircraft, became airborne.

To avoid the possibility of bomb damage at Brockworth, a likely Luftwaffe target, this diminutive aircraft had been fitted with Sir Frank Whittle's revolutionary gas turbine engine at Regent Motors in Cheltenham, where the Regent Arcade now stands. During these initial trials the E28/39 or Gloster Whittle made three hops reaching a height of only 1.8m. This was sufficient to distinguish the Brockworth airfield as the site of the first allied jet flight and therefore an international aviation heritage site.

According to Sir Ralph Robins, the Chairman of Rolls-Royce, "Frank Whittle's pioneering work on the turbojet engine is probably the most important mechanical invention this century. Certainly there can be few, if any in the world, whose lives have not been affected by it". It is this event which forms the fulcrum of Gloucestershire Aviation Collection's JET AGE Museum.

How was it that Britain's first jet aircraft came to be designed, built and flown for the first time in the rural tranquillity of Gloucestershire?

The surprising fact is that Gloucestershire can boast a greater association with aviation and aerospace than any other county in Britain.

This long tradition, which saw many famous aircraft types that were built by the Bristol Aeroplane Company and Parnall in the south of the county to the Gloster Aircraft Company in the north, continues today in Rolls-Royce engines at Filton to Messier-Dowty and Smiths Industries Aerospace near Cheltenham.

Gloster Meteor - Early History

The early story of the Gloster Meteor is intertwined with British efforts to develop turbojet engines. In 1929, a young British Royal Air Force (RAF) flight officer named Frank Whittle came up ideas for building an aircraft engine based on the gas turbine. Other researchers had played with the concept, but Whittle was the first to have the engineering and aeronautical skills to do something useful with it.

Since all earlier attempts to develop an aircraft engine based on the gas turbine engine had failed, and Whittle's notions were so new and unusual, he was generally dismissed by government and industry authorities. However, Whittle was stubborn enough to apply for a patent on his ideas in 1930, and continued to promote his engine concepts, with a remarkably lenient RAF giving him time and opportunity to pursue the matter.

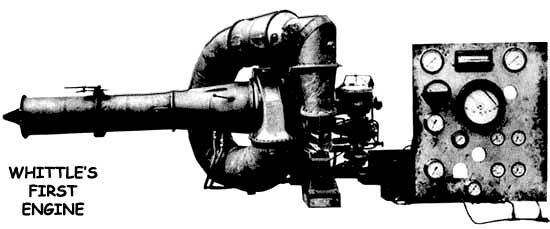

In 1936, Whittle set up a small firm named Power Jets LTD to pursue his ideas, and was soon applying for new patents. One was for a "bench-test" gas-turbine engine designated the "Whittle Unit (WU)". Whittle began tests of the WU in 1937. The tests were successful, if sometimes extremely frightening, with the engine having a nasty tendency to go into violent runaway operation. Fortunately, Whittle was not killed or maimed, and managed to get the WU working well enough that by 1938 the British Air Ministry began to provide him with moderate funds to continue his work.

In 1936, Whittle set up a small firm named Power Jets LTD to pursue his ideas, and was soon applying for new patents. One was for a "bench-test" gas-turbine engine designated the "Whittle Unit (WU)". Whittle began tests of the WU in 1937. The tests were successful, if sometimes extremely frightening, with the engine having a nasty tendency to go into violent runaway operation. Fortunately, Whittle was not killed or maimed, and managed to get the WU working well enough that by 1938 the British Air Ministry began to provide him with moderate funds to continue his work.

In June 1939, with the WU working in a reliable and impressive fashion, the Air Ministry ordered a flight-worthy engine, the "W.1", from Power Jets. In September 1939, the Air Ministry also ordered that Gloster design an aircraft, the "E.28/39", to test-fly the engine. In the meantime, Whittle was hearing rumors that the Germans were also working on "turbojet" engines, as they came to be known.

Things were still not smooth sailing for Whittle. The Air Ministry was interested in his engine, but it wasn't the highest priority, and by September Britain was in a war that the country was poorly prepared to fight. In fact, by the summer and fall of 1940, Britain was struggling against German Luftwaffe air fleets that pounded the island, with an invasion  seeming imminent.

seeming imminent.

Despite the disruption caused by the Battle of Britain, work on turbojet engines and aircraft continued at a low level. In fact, in 1940 the Air Ministry issued a request, designated "F.9/40", for an operational turbojet-powered fighter. Given that Whittle's W.1 and its possible derivatives appeared significantly underpowered, Gloster's chief engineer George Carter proposed a twin-engine aircraft with the company designation "G.41" for the specification.

The proposal was approved in November 1940, with a batch of twelve prototypes ordered on 7 February 1941. The G.41 was named "Thunderbolt" in September 1941, but in early 1942 it became apparent that this would cause confusion with the new American Republic P-47 Thunderbolt, and the name was changed to "Meteor". Some sources also claim that it was called "Rampage" during trials, though this appears to have been a cover name used for security purposes.

The first of two experimental E.28/39 test aircraft, which had the company designation of "G.40" and were known informally as the "Gloster Whittle", began taxi trials with an non-airworthy W.1X engine on 8 April 1941, with Whittle himself performing some of the tests, and Flight Lieutenant P.E.G. "Gerry" Sayer, Gloster's chief test pilot, performing a few "hops" off the runway that same day. After the aircraft was refitted with a proper W.1 engine, Sayer performed the first real flight in the aircraft on 15 May 1940, with everything going smoothly, and Sayer having nothing but good to say about the experience.

The first of two experimental E.28/39 test aircraft, which had the company designation of "G.40" and were known informally as the "Gloster Whittle", began taxi trials with an non-airworthy W.1X engine on 8 April 1941, with Whittle himself performing some of the tests, and Flight Lieutenant P.E.G. "Gerry" Sayer, Gloster's chief test pilot, performing a few "hops" off the runway that same day. After the aircraft was refitted with a proper W.1 engine, Sayer performed the first real flight in the aircraft on 15 May 1940, with everything going smoothly, and Sayer having nothing but good to say about the experience.

The second G.40 did not fly until March 1943. It would be lost due to a flight malfunction four months later, with the pilot baling out successfully. The first would eventually end up as a museum piece.

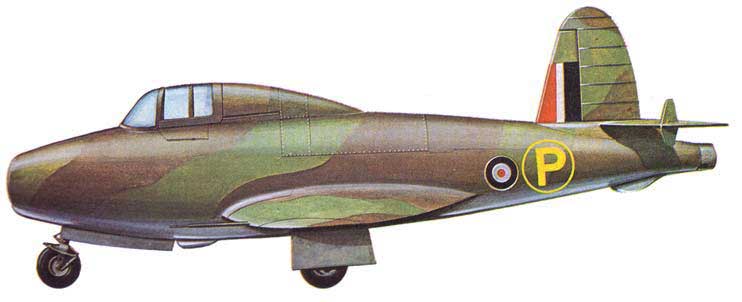

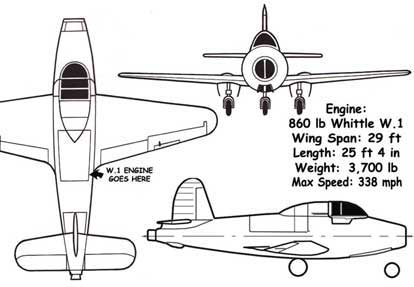

The G.40 was a simple all-metal "flying stovepipe" design, with a low-mounted straight wing and retractable tricycle landing gear. It was powered by a single Whittle W.1 engine, providing 850 lbf thrust. It had a wingspan of 29 feet, a length of 25 feet 4 inches, a maximum loaded weight of 3,700 pounds, and a modest top speed of 338 MPH.

Lutterworth and the Birth of the Jet Engine

By Roger Jones, The Whittle Society.

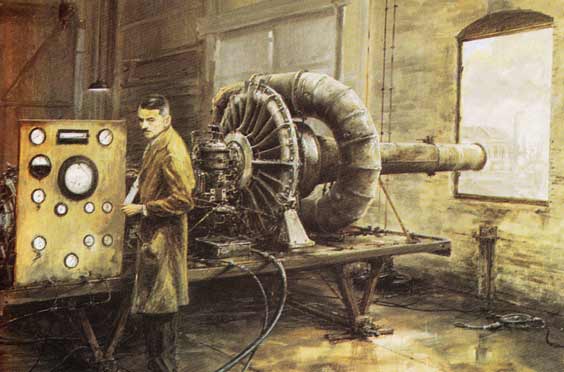

Frank Whittle first formed the idea of using gas turbines to drive aircraft at far higher speeds and altitudes than so far reached whilst still a RAF cadet at Cranwell. It was not until nine years later, having served as a test pilot and awarded a 1st class degree at Cambridge, that he was able to complete a proof of concept engine and ran it successfully at the British Thompson- Houston works at Rugby on 12th April 1937.

Unfortunately, in these early runs, the engine showed a distinct

tendency to run out of control so that BT suggested that it

might be safer if the  testing was continued up the road at a disused

foundry they owned at Lutterworth. Power Jets, the company that

he had formed to develop his ideas, moved into the Ladywood Works

on the east side of the Leicester Road at the beginning of 1938

with one employee. Here, two further versions of the original

engine were tested and the team gradually grew as talented graduates

and experienced technicians were recruited. In July 1939 with

war looming, the government placed an order for a flight engine.

Image of the test bed at Ladywood in Lutterworth Museum.

testing was continued up the road at a disused

foundry they owned at Lutterworth. Power Jets, the company that

he had formed to develop his ideas, moved into the Ladywood Works

on the east side of the Leicester Road at the beginning of 1938

with one employee. Here, two further versions of the original

engine were tested and the team gradually grew as talented graduates

and experienced technicians were recruited. In July 1939 with

war looming, the government placed an order for a flight engine.

Image of the test bed at Ladywood in Lutterworth Museum.

Locals still remember the influx of "boffins" who were billeted on local households and the continuous sound of engine testing claiming that when it sometimes when it stopped in the night the silence woke them up. Meanwhile an engine mounted on a truck was used to help clear snow from the High St. and a hawthorn hedge in line with the efflux of engines under test burst into flower in February.

After building and testing a interim engine the flight engine,

W1, was assembled and run in April 1941. On 15th May it flew at

Cranwell in the specially designed Gloster E28/39 aircraft. Some

nine months earlier, unknown to the allies, the Germans had flown

an experimental gas turbine engine designed by Otto Von Ohain.

After building and testing a interim engine the flight engine,

W1, was assembled and run in April 1941. On 15th May it flew at

Cranwell in the specially designed Gloster E28/39 aircraft. Some

nine months earlier, unknown to the allies, the Germans had flown

an experimental gas turbine engine designed by Otto Von Ohain.

With the government at last behind the project, W1 was further developed and a new engine designed and tested to power a twinengined fighter, the Gloster Meteor. Meanwhile a production facility was being built some seven miles up the road in Whetstone. Power Jets finally moved out of Ladywood Works in 1946

First British Jet Pilot:  Sayer's first actual flight in the E28/39 consisted of some short hops of between 100 and 200 yards at Hucclecote on the 7th April 1941 while the aircraft was still fitted with its first W1X (Taxi only) engine. The aircraft was then moved to Cranwell where it received its flight ready engine. The first offical flight took place at 7pm on the 15th May 1941 and lasted 17 minutes due to its minimal fuel load. Over the next thirteen days he completed a further ten hours of test flights at altitudes up to 25,000 feet with the longest of just under an hour with its maximum load of 81 gallons. Sayer was killed flying a Typhoon in 1942 on a visit to RAF Acklington in Northumberland. The cause of the accident was never determined but it is thought that he collided in the clouds with the other aircraft he was flying with. Following the loss the task of continuing the flight test program fell to his assistant Michael Daunt who would go on to test-fly the early Meteors. |

|

|

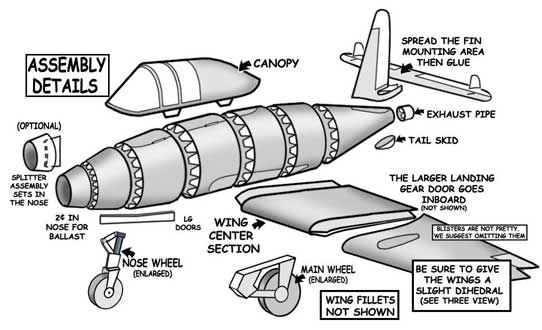

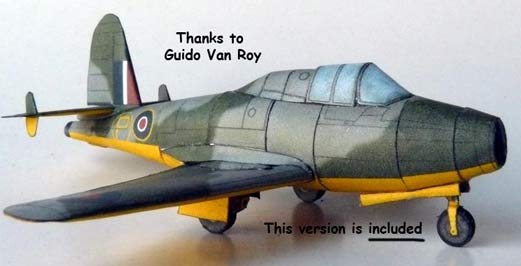

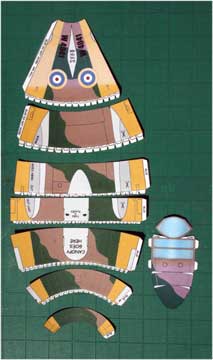

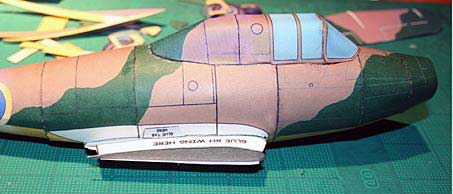

I have repainted the Gloster model in a later color scheme of grey and green camo. This version sported both the prototype "P" marking and the serial with the "/G" suffix indicating permanent guarding when on the ground. As usual, I built the model in 1/72 scale, which is small compared to the original large size ! Feel free to add this to the model folder. Guido van Roy |

|

Monument guarding the site of the first Gloster E28 flight |

...Great stuff there ! I have not yet found the time to print nor assemble the model, but it looks familiar... If you allow me some comments though : I feel that all colours including the markings are much too vivid - apart from the bright yellow undersides that is. Two color variations would be possible :aluminium paint allover (as initially flown) and grey/green camo that at one time replaced the well-known green/brown. Most of the time, the serial would have been suffixed by "/G" to indicate that the aircraft was to be permanently guarded on the ground - obviously a safety measure to keep the new technology out of reach for curious eyes. Guido/Apr 30, 09 (Co-designer of this Gloster E29/39)

ANS: I agree the colors are vivid BUT when printed they become just about right. Good info about the "G"..chip

Sorry, the Gloster E28/39 was built for proof of concept not as a fighter. The first jet fighter/bomber was the Me 262. The German government always supported innovative technology and as such their designs in many fields were often far superior to the western allies. Unfortunately the British government listened to their science advisors who suffered from the "Not invented here" syndrome and slowed innovation to a crawl! (Brian Newman)

I took an extra build step, rather than overlap the fuselage sections; they are connected using strips which allow the sections to butt up against each other. Bob Penikas |

|

|

|

|

|

|

|

|

Modeln Pal, Bob Martin, has figured out how to make fabulous clear windscreens and even complex canopies using common clear packing tape. Its easy !! Step by Step instructional Modeln Pal, Bob Martin, has figured out how to make fabulous clear windscreens and even complex canopies using common clear packing tape. Its easy !! Step by Step instructional |

Gloster E28

BRITISH JET ENGINE DEVELOPMENT

Despite Whittle's success, development of the operational G.41 fighter was slow. Power Jets was not in a position to mass-produce the Whittle engine, and trying to find another firm with adequate resources led to a two-year delay in production. As a result, progress of the G.41 project ended up tracking the somewhat

Despite Whittle's success, development of the operational G.41 fighter was slow. Power Jets was not in a position to mass-produce the Whittle engine, and trying to find another firm with adequate resources led to a two-year delay in production. As a result, progress of the G.41 project ended up tracking the somewhat  convoluted path of early British turbojet development.

convoluted path of early British turbojet development.

By October 1940, the Air Ministry was interested enough in the Whittle engine to arrange for production of the W.2B by Rover. Unfortunately, the term "misarranged" is probably more appropriate, since Power Jets and Rover worked at all times at cross purposes, with the confusion aggravated by contrary instructions from the British Ministry of Production. The jet engine development effort slowly strangled on its own red tape until 1942, when Rolls-Royce's Ernest Hives took S.B. Wilks of Rover out to lunch and, as the story has it, asked Wilks: "Give us this jet job and we'll give you our tank-engine factory in Nottingham."

Rolls-Royce wanted the jet engine and knew what they wanted to do with it, and indeed, beyond the end of the millennium, still does. In fact, the company's own engineering staff had been working on jet propulsion since 1939, and in making the swap Rover was giving away something they didn't really want, while Rolls-Royce was obtaining a treasure.

A W.2B engine, plugged into the tail of a Vickers Wellington bomber, was test-flown that November, and after further improvements was test-flown in the second G.40 Gloster Whittle in March 1943. The W.2B was providing 1,600 lbf thrust by this time. Rolls-Royce worked with Whittle to finally get an uprated version of the W.2B engine in production as the "Welland I".

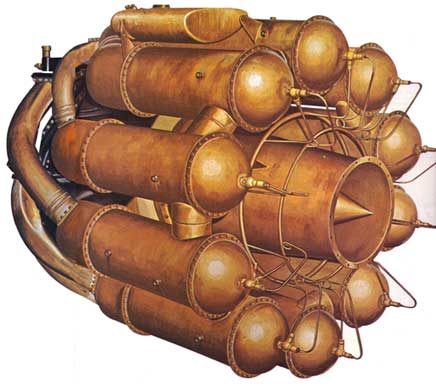

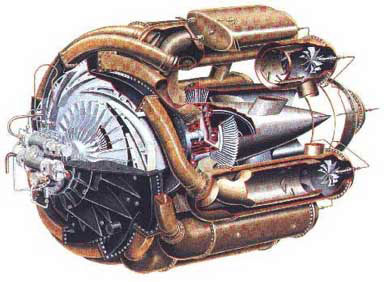

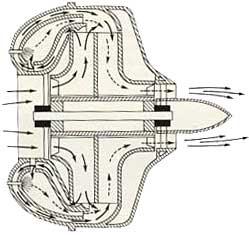

The Whittle WU, W.1, and W.2B were all "centrifugal-flow" engines, which used a turbine similar to a pump impeller to force air into a set of combustion chambers or "combustors" ringed around the engine. The flow of air went through the combustors from back to front, with such a "reverse flow" arrangement reducing the length of the engine. These engines had only the broadest resemblance to a modern military turbojet engine, but the same design concepts would not be out of place in a modern helicopter turboshaft engine.

The Whittle WU, W.1, and W.2B were all "centrifugal-flow" engines, which used a turbine similar to a pump impeller to force air into a set of combustion chambers or "combustors" ringed around the engine. The flow of air went through the combustors from back to front, with such a "reverse flow" arrangement reducing the length of the engine. These engines had only the broadest resemblance to a modern military turbojet engine, but the same design concepts would not be out of place in a modern helicopter turboshaft engine.

Rolls-Royce then reworked the design to feature straight-through air flow through the combustors and better fuel and oil systems, resulting in the "Derwent I", providing 2,000 lbf thrust. The Derwent was refined in various versions up to the Mark IV, which provided 2,450 lbf thrust.

Stanley Hooker, who had been in charge of the Rolls-Royce design team that refined the Derwent, visited the US in the spring of 1944 and found that General Electric was developing two turbojet engines with thrust ratings of 4,000 lbf or higher. Hooker, realizing that the British had been thinking small, went back to Britain and initiated a fast-track project to build a new, much more powerful centrifugal-flow engine. The result was the "RB.41 Nene", which was first bench-tested in October 1944 and provided 5,000 lbf thrust. The Nene was the world's most powerful engine at the time, and it was also simple, cheap, and reliable. The Nene was manufactured in large numbers, with versions made in Canada, Australia, France, the US, and the USSR.

The Nene was such a good engine that Rolls-Royce decided to build a scaled-down version, which was designated the "Derwent 5" though it had little direct relationship to earlier Derwent marks. The Derwent 5 was first bench-tested in June 1945, with the test engine providing 2,650 lbf thrust.

The Nene was such a good engine that Rolls-Royce decided to build a scaled-down version, which was designated the "Derwent 5" though it had little direct relationship to earlier Derwent marks. The Derwent 5 was first bench-tested in June 1945, with the test engine providing 2,650 lbf thrust.

In the meantime, since early 1941 de Havilland had been working on their own centrifugal-flow turbojet engine, derived from earlier Whittle patents and not the W.1 design. The result was the de Havilland "Halford H.1", which was first bench-tested in April 1942. By late 1943, the H.1 had been refined into the "Goblin" engine, which provided 2,300 lbf thrust and would power the de Havilland Vampire fighter.

British jet engine development was following yet another parallel track at the time. As far back as 1939, Metropolitan-Vickers ("MetroVic"), a Manchester firm that specialized in steam turbines, was working on what would become the first British "axial-flow" turbojet engine, a design that was almost entirely unlike the centrifugal-flow engines being developed by Whittle and others. Such axial-flow engines featured sets or "stages" of fan blades arranged around a central axle, compressing air into a combustion chamber, which was followed by another set of fan blades that kept the axle spinning. The axial-flow turbojet would prove to be the way of the future for high-speed combat aircraft, though the centrifugal-flow engine would become the basis for modern helicopter turboshaft engines.

|

|

Specifications for the Gloster E28

|

Length: 25 ft 4 in Wingspan: 29 ft Height: 8 ft 10 in Wing area: 146 ft² Airfoil: G.W.2-section Empty weight: 2,886 lb Loaded weight: 3,748 lb Powerplant: 1× Power Jets W.1 turbojet, 860 lbf Fuel capacity: 81 gallons Performance Max speed: 338 mph at 10,000 ft Range: 410 mi Endurance: 56 minutes Service ceiling: 32,000 ft Rate of climb: 1,063 ft/min Thrust/weight: 0.21 Armament Guns: None fitted but provision for four 0.303 in (7.7 mm) Browning machine guns |