Northrop XB-35 Flying Wing Experimental Heavy Bomber

Although the XB-35 was ordered as early as 1941, it was obvious by 1944 that the flying-wing bomber was going to miss World War II and would then be obsolescent. In preparation for the next war, a jet-powered version was begun. The piston engined XB-35 flew in June 1946, and the jet YR-49 in October 1947.The YB-35 initially had contra-rotating propellers, and had endless trouble with the gearboxes and unwanted yaw, much delaying the program.

The YB-49 performed well, but during pull-out tests the No. 2 aircraft tumbled backwards and the outer wings fell off. Edwards Air Force Base was named after the unfortunate test pilot. All sorts of versions were planned for bombing, reconnaissance and electronic intelligence, but while about a dozen aircraft were under completion, the whole project was cancelled and all were scrapped.

One YRB-49A was in fact completed and made its first flight on 4 May 1950. This aircraft had six Allison J35-A-19 turbojets, four of which were buried in the wing and the other two suspended in pods beneath it. The YRB-49A carried a six-man crew and its equipment included the latest high-altitude cameras, situated in a compartment at the rear of the fuselage nacelle.

XB-35 Flying Wing

The final chapter in the odyssey of Jack Northrop's quest for the true flying

wing is a microcosm of all of the disappointments and glorious moments one

could expect in the development of an aircraft as unconventional as the flying

wing bomber. The piston-engined XB-35, and its jet-powered successor, the

YB-49, were immensely pleasing to the eye, but to conservatives within the

aeronautical community, they probably did not "look right", and therefore

their ultimate success was in doubt.

The final chapter in the odyssey of Jack Northrop's quest for the true flying

wing is a microcosm of all of the disappointments and glorious moments one

could expect in the development of an aircraft as unconventional as the flying

wing bomber. The piston-engined XB-35, and its jet-powered successor, the

YB-49, were immensely pleasing to the eye, but to conservatives within the

aeronautical community, they probably did not "look right", and therefore

their ultimate success was in doubt.

The flying wing bombers enjoyed all the usual financial support and governmental interest normally associated with a wartime program. They also suffered through the chaotic period that came with war's end. The program endured, however, because of the enormous potential demonstrated by the unique aircraft. The enthusiasm for the program that was demonstrated by the Northrop "family" was shared to a great extent by many of the technical and management people of the Army Air Forces. Their foresight, assistance, and encouragement kept the development program going through the rough times.

Project MX-140, as the bomber program was called, was officially initiated by contract action on November 22, 1941, following previous discussions between Northrop and Air Force officials regarding performance requirements for a high altitude, long range, heavy bombardment airplane. The numbers that spelled out the airplane's vital statistics in formal Airplane Specifications NS-9A gave no hint of the sheer expansiveness of the airplane, and its spectacular performance. They also gave no hint of the problems that would attend its design, construction, and flight evaluation.

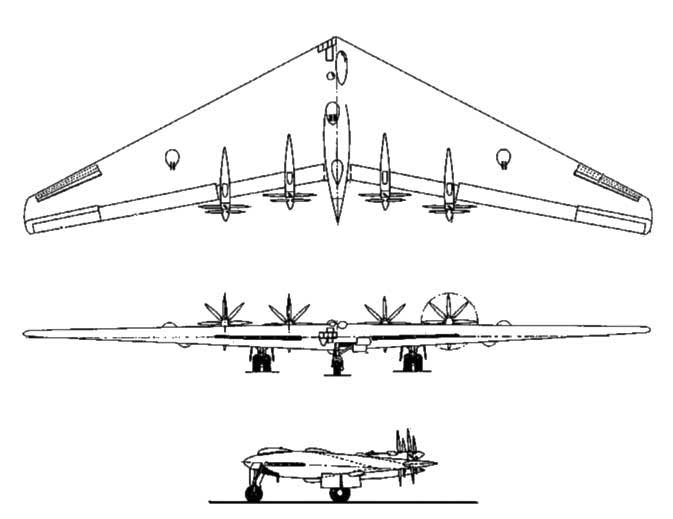

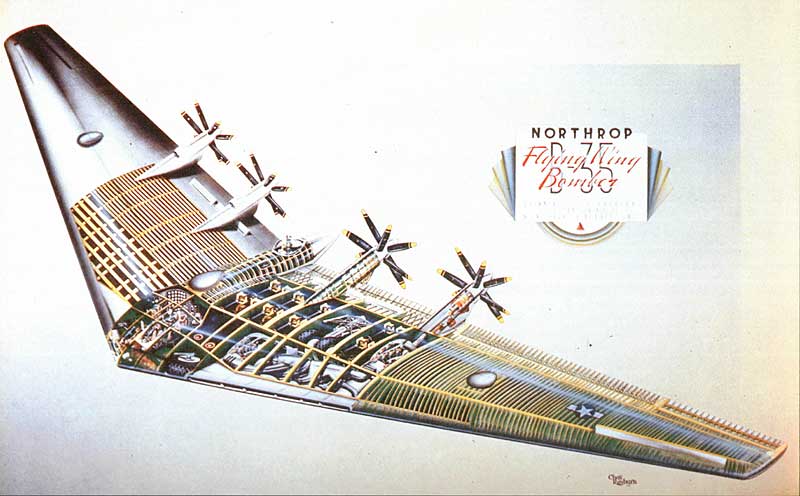

In size, the XB-35 would dwarf the B-17 Flying Fortress, with wing area and gross weight almost three times those of the legendary heavy bomber. The unconventional control system reflected years of study, wind tunnel tests, and flight test data gleaned from the N-1M and N-9M programs. The elevons and rudders were power operated. Thus, it was necessary to provide an artificial "feel" to the controls for these surfaces. This was accomplished by springs attached to the control wheels and rudder pedal mechanisms which returned the controls to neutral and provided the "feel" necessary to prevent over control of the rudder and aileron movement of the elevons. "Feel" to the operation of the control columns for elevator control was provided by ram air pressure in a bellows attached to the control columns.

Trim flaps, elevons, and landing flaps were arrayed in order from each wing tip inboard along the trailing edge of the wing. The electrically actuated trim flaps at the wing tips were used by the pilot in much the same manner as elevator or aileron tabs. Their primary purpose was to balance the large diving moments produced by the split trailing edge landing flaps, minimizing the upward deflection of the elevons and thus permitting them to be deflected over a greater range as elevators. The trim flaps could also be operate differentially to counteract unbalanced rolling moments.

Rudders consisted of split flaps that were incorporated as an integral part of the trim flaps at the trailing edges of the wing tips. Operated one at a time by the pilot's movement of the corresponding rudder pedal, the surfaces deflected above and below the trim flap. Simultaneous movement of the rudder pedals, which were not interconnected, opened both rudders for speed control.

Despite the unconventional arrangement and function of the control surface, the conventional control column with wheel and rudder pedals made the pilot feel right at home.

Contributing to increased longitudinal stability at high angles of attack were wing tip slots with automatically controlled cover doors. These doors were set to open at high lift coefficients, preventing wing tip stall and increasing stability. A switch actuated by the landing gear also opened the doors when the gear was down.

One of the primary concerns in the layout of the aircraft was the cockpit design. Despite unorthodox configuration, space was not a problem. The aircraft's cockpit featured convenient control and instrument arrangements and excellent visibility.

The pilot seated in the plexiglass bubble to the left of the aircraft centerline. the copilot was to the right of and below the pilot, behind a large window in the leading edge of the wing. An engineer's station was also in the forward part of the crew nacelle, as were stations for the radio operator, navigator, bombardier, and gunners. The mid-section of the crew nacelle had sleeping facilities for a relief crew of six people, a requirement for operational missions of 10,000 miles where crew fatigue would be a primary consideration. The after section contained the gunner's station. The seven-foot headroom in the crew's quarters was certainly adequate, and the accommodations were the first of such extent and complexity to have been incorporated into such a radical design.

A brief look at the overall arrangement would not be complete without at least some reference to the "main battery" of the XB-35-its eight bomb bays. Capable of carrying 10,000 pounds of conventional bombs (but not an atomic weapon), the bays were incorporated in the wings, arrayed four on each side of the crew nacelle. Defensive armament consisted of twenty 0.50 caliber machine guns contained in seven remotely controlled turrets: four on the wing, two on the crew nacelle, and a tail stinger.

The power plants were also vital to the successful operation of this revolutionary weapons system. They consisted of four Pratt & Whitney Wasp Major engines, one pair each of R-4360-17 and R-4360-21 series equipped with single stage GE turbo-superchargers, each delivering 3000 hp. The "Achilles' heel" of the installation was the propulsion power train. Each engine was coupled to a remote gear box assembly by an extension drive shaft. Two sets of four-bladed, dual rotating, reversible pitch, full feathering, Hamilton Standard propellers were mounted on dual concentric shafts extending from each gear box. The engines were completely enclosed within the wing, an arrangement that imposed severe requirements on the aircraft's structure. Superchargers, intercoolers, oil coolers, and fans for ground-cooling and cooling at low speeds were located in the wing, as were cooling ducts and controls to diffuse the air around the engines and expel it through flaps near the trailing edge.

Translating 100 pages of statistics and technical terms into 100 tons of complex, futuristic airplane proved to be an almost insurmountable task. From contract approval in November 1941, to first flight of the XB-35 on June 25, 1946, there were interminable delays. At one time or another, changes in priorities, design and engineering difficulties, problems with ground testing engines, shortages of engineers, indecision by management, constant shortages of government furnished equipment (GFE), and a myriad of other factors contributed to the lengthy production process. Of all the obstacles to orderly progress, the most frustrating involved the highly unsatisfactory working relationship between two major aircraft builders, Northrop and Martin.

Following an initial contract for one XB-35 airplane, approved November 22,1941, Northrop received an order for an additional XB-35 as a backup in January 1942.Later that year, another 13 service test models were contracted for, to be designated YB-35. By June 1943,with a production contract for 200 B-35s on hand, and the first flight date still out of sight, it was apparent that Northrop production and engineering facilities, already heavily committed to production of P-61 Black Widow night fighters, were inadequate for the job. If the program was to proceed, engineering and production assistance would have to come from some other source.

By the end of June 1943,the Glenn L. Martin Company of Baltimore, Mary- land, at the AAF's request, had contracted to assist Northrop in engineering the XB-35 and YB-35 and also to manufacture 200 production B-35s. Delivery of the first production airplane was to be in June 1945. From a tactical and logistical standpoint, there was no further need for Martin's B-33 Super Marauder. The production contract was cancelled and the available engineering talent was diverted to the XB-35 project.

The engineering "partnership" that evolved between Northrop and Martin not only failed to produce a single B-35, but also engendered confusion, delays, and even ill will. Engineering work was carried out simultaneously at both companies on "X" "Y", and production airplanes, resulting in indecision, lack of coordination, and unresolved questions of priorities and responsibilities. Loss of engineers to the military draft aggravated an already untenable situation. As of March 1944, Martin had made no commitments to materials and had not started tooling. The program was already 18 months behind schedule and relations between Northrop and Martin were considerably strained.

In May 1944, the AAF reviewed the entire program. It was the opinion of some officials that the attitude of Martin management was a significant factor in the lack of progress to date. Never enthusiastic about producing any air- plane not of their own design, Martin continually put forth more reasons for not continuing their part of the production program. Martin management expressed little faith in the B-35 as a practical airplane.2 The AAF decided to cancel Martin's production contract, with the understanding that Martin would continue to give Northrop engineering assistance on the "X" and "Y" models. Additional engineering assistance would be made available from the Otis Elevator Company. No production engineering was to be undertaken at that time. In effect, it was a conscious decision that the B-35 would be a post-war airplane.

December 1944, marked a significant turning point in the development of the Flying wing bomber. By that time, both Germany and England were using turbojet-powered aircraft in combat. The Messerschmitt Me 262 first appeared on combat in July 1944, followed shortly by the first victory of the British Gloster Meteor over a German V-1 missile. In the United States, the Bell XP-59A Airacomet had flown in 1942, and by late 1944 the Lockheed P-80A Shooting Star was almost operational. It was becoming obvious that the world was on the threshold of the jet age and piston engined warplanes such as the B-35 would eventually become obsolete. On the other hand, a B-35 fitted with turbojet engines began to look extremely attractive.

Consequently, in December 1944, series of modification and conversion programs began that lasted until the final days of the Flying wing bomber. Proposals for changes in the aircraft mission, combined with alternative power plant arrangements led to a bewildering variety of aircraft configurations and designations. After years of conversion and modification programs that ensued, only six were completed and flew, three of which had piston engines, and three with turbojets.

It was another year and a half after the modification proposals in December 1944,before an XB-35 would finally take to the air on its maiden flight. It was a frustrating period marked by engine development problems, delays due to lack of experience in construction of very large aircraft, late deliveries of major GFE items, and the acute conversion problems experienced by the defense contractors with the end of World War II.

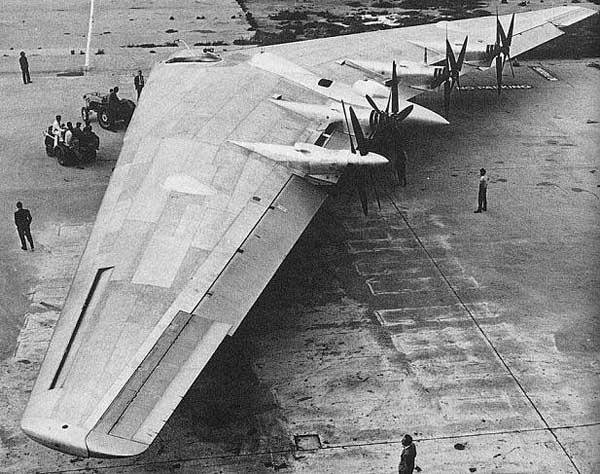

The majestic XB-35 moved for the first time on its own wheels and under its own power on May 16,1946. The occasion was a slow taxi test, and at the controls was the Northrop test pilot who would shepherd the Flying Wings through four turbulent years of flight tests, Max Stanley. Accompanying Stanley as copilot was Fred Bretcher, who would be at his side during much of the flying program.

As the XB-35 began to move slowly down the 100-foot wide runway at

Hawthorne, its 172-foot wing span seemed to dwarf even the building of the

nearby Northrop plant from which it came. To Jack Northrop, standing at the

flight ramp, the sound of four R-4360s running at the same time, even at taxi

power setting, must have been over-whelming. As Max Stanley gave him a

"thumbs up" at the conclusion of the satisfactory test, Jack Northrop surely

must have been elated at this sign of pro gress and the prospect of a first flight

in the not too distant future.

gress and the prospect of a first flight

in the not too distant future.

The day finally came. After dozens of high-speed taxi runs, during which speeds as high as 115 mph were attained, the aircraft seemed ready. June 25, 1946, was picked for first flight. Only a small crowd of sightseers and media people watched Max Stanley, Fred Bretcher, and Flight Engineer O. H. Douglas climb up into the flight deck, which by 10:00 A.M. was like an oven in the hot California sun. Absent were the thousands of designers, engineers, and shop workers who had labored for years over the engineering and construction of the bomber. They had been restricted to their desks and work stations by company executives concerned over crowd control during the momentous occasion. Absent also was the man whose creative genius had spawned the giant wing, Jack Northrop, who, abiding by company policy, also remained at his desk, in an incredible display of self discipline.

"This is it!" With those words, Max Stanley advanced the throttles and, with 12,000 hp pushing the huge wing along, the XB-35 thundered down the narrow runway at Hawthorne. At 120 mph, Stanley slowly eased the control column back and at 10:32 a.m., the Flying Wing flew for the first time. Finally, after years of planning and experimenting, Jack Northrop had accomplished what Junkers, Soldenhoff, and other early pioneers had only dreamed of. The first flight was essentially a ferry flight from Northrop Airport to Muroc Army Air Base. The idea was to get to Muroc with a minimum of trouble, but at the same time to learn about the flying characteristics of the airplane. Stanley tested the controls with the landing gear up and down several times. Highest airspeed attained was 200 mph, as the Flying Wing, with its P-61 Black Widow chase plane in company, cleared the mountains and began its descent to Muroc. As a precautionary measure, a no-flap approach was made, with a smooth touchdown at 112 mph. The 44-minute flight was un- eventful, except for erratic operation of a propeller governor. Everyone associated with the project was jubilant, anxious to press on with the flight testing and prove the design once and for all.

But the minor problem with the propeller governor did not fade away. The XB-35 flew twice more in the next three months, accumulating only three hours of flight time by mid-September 1946. Problems with the Hamilton Standard propeller governors became chronic, with the propellers continually "hunting" around a constant speed setting and "creeping" in fixed pitch during air operations. Additionally, there was evidence that the huge counter-rotating propellers were operating under excessive stress, leading to a restriction of 80 hours operating time due to the danger of fatigue.

Another major problem with GFE arose. Troubles centered around the gear box assembly that coupled each engine to its propeller by means of a drive shaft from engine to gear box, and a dual concentric shaft from gear box to the counter-rotating propellers. Propellers and engine vibration caused frequent failures of the gear boxes. A flexible, vibration absorbing gear box mount was a vital necessity for successful flight testing.

At the beginning of 1947, the Flying Wing program consisted of one XB-35 flying, albeit occasionally, one XB-35 about to finish engineering inspection in March, two YB-49s (the jet engine configured B-35) and six YB-35s (built to XB-35 specifications) either complete or in the final stage of assembly. The remaining five YB-35s on the existing contract were to be equipped with more modern navigation and weapons systems, and thus were to be designated YB-35As.

The first XB-35 flew only intermittently during 1947, plagued by landing gear doors failing to retract and the continuing gear box malfunctions. The second XB-35 flew for the first time almost one year after the first, on June 26, 1947. It too, began to experience the same difficulties as the first aircraft. In desperation, the Air Materiel Command cancelled dual rotation propellers for the YB-35 and decided to use single rotation gear boxes and 15-foot diameter Hamilton Standard propellers, despite the resulting deterioration in performance.In April, both XB-35s were grounded for installation of the changes.

|

Cockpit of an XB-35 Flying Wing |

Specifications for the Northrop XB-35 Flying Wing

|

Crew: 9: pilot, copilot, bombardier, Performance |

|

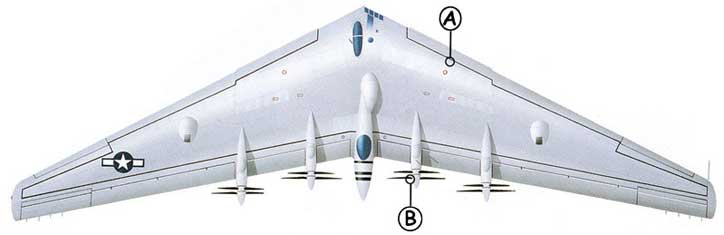

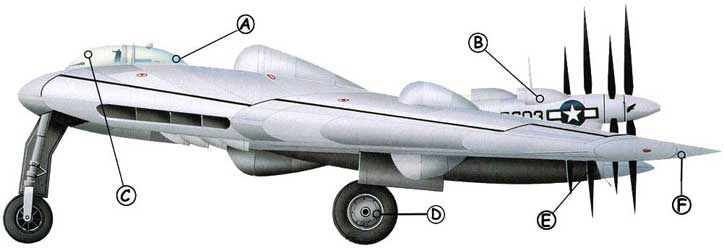

Northrop XB-35 Cutaway |

|

|

| A: With a massive wing area of just under 4,000 sq. ft the XB-35 had a gross weight of 94.8 tons. Empty weight was just over 40 tons. | B: The XB-35 prototype was built with four pusher contra rotating propellers. |

|

||

| A: The flying wing concept was compromised to accommodate a canopy for the pilot's position. |

B: The YB-49 replaced four piston engines with eight Allison J35 turbojet engines. |

C: A crew of up to nine would have manned a service B-35, consisting of a pilot, co-pilot, bombardier, navigator, flight engineer, radio operator and three gunners. |

| D: The single nose wheel retracted to the left into the wing, while the two large tires and the main gears retracted rearward into the wing. | E: The massive propellers of the XB-35 were powered by four Pratt&Whitney R-4360 Wasp Major radial engines that also equipped the Boeing B-50 and Convair B-36. | F: Without conventional control surfaces, the XB-35 used two sets of decelerons, elevons (for pitch and roll) and split flaps for landing. |

Model is still under development 11/11/09.