Pawnee Glider Tug - $$5.95

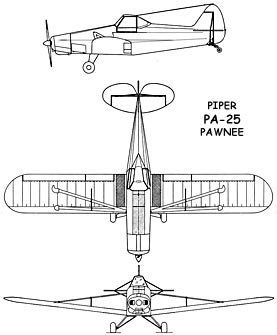

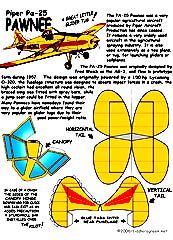

The Pawnee is a single engined low-wing monoplane constructed of steel tubing and covered with fabric. The emphasis of this design was on pilot safety with the fuselage structure designed to collapse progressively during a low speed crash, typically experienced during crop spraying operations.

Piper PA-25 Pawnee Glider Tug and Crop Sprayer

The Pawnee had a very strong undercarriage with low-pressure 'doughnut' tires and pneumatic oleo struts to absorb the rough landings and take-offs from the dirt roads of the farms. The engine was originally a 150hp Lycoming but that was soon up rated to a 235hp Lycoming flat four 0-540 six-cylinder unit. The spray tanks contained 150 gallons and were interchangeable with hoppers for crop dusting with 1,200 pounds of dry powder chemicals covering a swath of 60ft. The Piper Pawnee was, and remains, a very strong and purpose-built workhorse now regarded as a classic.

Many Pawnees have nowadays found their way to a glider airfield where they are very popular as glider tugs due to their good power/weight ratio.

|

|

|

Wow. A couple more sweet looking birds. Have to build a Piper mobile for my Piper. TW

Piper PA-25 Pawnee Glider Tug

As

airplane design matured, the business of crop-dusting—or

“aerial application,” the preferred professional term—also

became more sophisticated. Farmers became increasingly aware of,

and dependent upon, crop-dusting aircraft to efficiently fertilize

their crops and dispense chemical pesticides on destructive pests.

As

airplane design matured, the business of crop-dusting—or

“aerial application,” the preferred professional term—also

became more sophisticated. Farmers became increasingly aware of,

and dependent upon, crop-dusting aircraft to efficiently fertilize

their crops and dispense chemical pesticides on destructive pests.

The scores of biplane military trainers developed in the World

War II era later turned into an unexpected windfall for the crop-dusting

industry. The early days of crop dusting were often hazardous

for the pilot because lightweight airplanes with weak frames were

modified for use as crop-dusters—this situation changed

for the better immediately after the war, when sturdily built

surplus aircraft with improved pilot visibility were soon transformed

into crop dusters.

The famous Boeing/Stearman

Model 75 Kaydet two-seat biplane, (right) developed

in the mid-1930s as the primary trainer for both the U.S. Army

Air Corps and the U.S. Navy (under their military designations

of PT-17 and N2S, respectively), became a mainstay of the post-war

crop-duster industry.

More than 8,000 Kaydet's (and variants) were manufactured in a 10-year span before production ceased in 1945, and thousands were sold as post-war surplus for as little as $250 apiece. The robust Kaydet's fabric-covered control surfaces, common in the 1930s, were usually replaced with a metal skin, more powerful radial engines were installed and a hopper was retrofitted into the front cockpit to contain the crop-dusting load.

Piper's venerable J-3 Cub, in which 80 percent of all United States military

pilots during World War II received their initial flight training,

was also transformed into another popular post-war crop-duster.

The Cub's small size and agility permitted it to be flown from

short dirt runways that could not support larger aircraft but,

when equipped with more powerful engines, many Cubs could carry

1,000-pound crop-dusting loads.

The piloting skills required for crop dusting were usually passed

along in informal flight sessions, treated as more of an art form

than the sophisticated science that it was. Pilots were taught

how to fly low, with their wheels almost touching the crops, as

a method to reduce “chemical drift”—fertilizer

or pesticides straying into the wrong areas. Obstacles seemed

to await them at every turn.

The piloting skills required for crop dusting were usually passed

along in informal flight sessions, treated as more of an art form

than the sophisticated science that it was. Pilots were taught

how to fly low, with their wheels almost touching the crops, as

a method to reduce “chemical drift”—fertilizer

or pesticides straying into the wrong areas. Obstacles seemed

to await them at every turn.

Crop dusters were always clipping

their tails on water towers, hitting fence posts or pulling up

without seeing a string of electric or telephone wires—unseen

dangers that often meant injury or death to the pilot.

Recognizing the double dangers of crop spraying: the natural dangers

of low flying and the added hazards of the often toxic chemicals

they delivered to the fields, several aircraft manufacturers began

to offer dedicated crop-spraying aircraft.

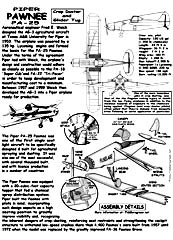

One of the best known and most widely used is the Piper PA-25

Pawnee (the Piper company named most of its light aircraft after

native North American tribes). The PA-25 first appeared in 1956,

replacing the Stearman and other surplus aircraft in the trade.

The company had recognized the nature of the risks involved by consulting, during the design stage, the Crash Injury Research Unit of Cornell Medical College. The Piper designer had appreciated that the chances of his aircraft ending up as a pile of parts after colliding with a windmill, barn or an old oak tree, or simply flying into the ground on some Midwestern farm, was high.

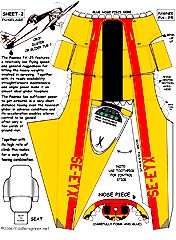

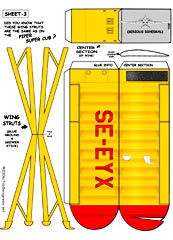

The pilot was given an excellent view from a cockpit placed high on the fuselage of the low-wing monoplane. The wings were cranked to get the spray bars running along the trailing edge as close to the crops as possible. The fuselage was designed to protect the pilot, the cockpit being in effect a strong capsule that was sufficiently substantial to remain undamaged even in a head-on collision.

To aid the possibility of the pilot's survival, the metal fuselage

was designed to fail progressively; for example, the fuselage

longerons were given a slight outward set so that in the slow-speed

crashes associated with spraying they would bulge outwards, absorbing

kinetic energy, and for that reason all heavy fittings were forward

of the cockpit area. The cockpit had a false floor with a l0 inch

gap to absorb energy in a pancake-type crash, and it also had

large opening windows on both sides.

To aid the possibility of the pilot's survival, the metal fuselage

was designed to fail progressively; for example, the fuselage

longerons were given a slight outward set so that in the slow-speed

crashes associated with spraying they would bulge outwards, absorbing

kinetic energy, and for that reason all heavy fittings were forward

of the cockpit area. The cockpit had a false floor with a l0 inch

gap to absorb energy in a pancake-type crash, and it also had

large opening windows on both sides.

The

other hazard in crop spraying, which was the contamination of

the airframe and cockpit by toxic chemicals, was made less dangerous

by positive ventilation of the cockpit with the air intake high

enough to avoid the spray fallout. The ventilation air flow also

lightly provided positive pressure to the fuselage to keep out

chemicals. At the end of the day the entire top section of the

fuselage could be removed in a minute or so for cleaning.

|

|

|

|

These pictures (upper two) are of a Pawnee i did up to match our tow plane at the gliderport im taking lessons at. The landing gear on some of the models I've built including this one is Sullivan 3/4 in. tail wheels that i got while getting parts for my remote control models. im building this and one of the 1-26 gliders as a display for our glider club to have present at the NAS Oceana airshow to promote glider flying. |

|

|

|

|

| Cockpit of the Piper PA-25 Pawnee. |

Specifications for the Piper PA-25 Pawnee

|

Crew: One Capacity: 120 US gal or 1,200 lb of chemicals Length: 24 ft 9 in Wingspan: 36 ft 2 in Height: 7 ft 2 in Wing area: 183 ft² Empty: 1,457 lb Loaded: 2,900lb Maximum takeoff: 2,900 lb Powerplant: 1 x Lycoming O-540-B2B5, 235 hp Performance Maximum speed: 117 mph Range: 300 miles Service ceiling: 13,000 ft Rate of climb: 630 ft/min (at MTOW) Wing loading: 15.9 lb/ft² Power/Mass: 0.0810 hp/lb |

|

| Investigators from the National Transportation Safety Board worked in a warehouse outside of Greeley to piece together the wreckage of the Piper Pawnee that collided with another airplane north of Boulder CO. |