Spoke Wheels Tutorial

With this tutorial we'll show you how to make Spoke Wheels with thread. Made possible with the help of Bob Martin, and Norman Gorn. Thanks guys!

Spoke Wheels Made Easy

|

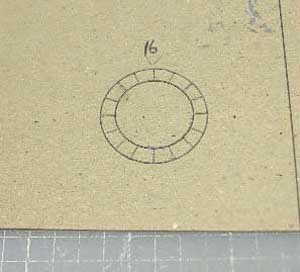

First step make a template the size of the wheel you want to make... You can just cut out one of our wheels from the model and trace around it. |

|

Next cut 16 notches around the outside of the wheel for our thread to go in. |

|

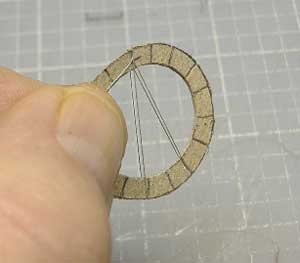

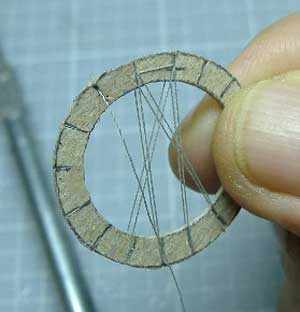

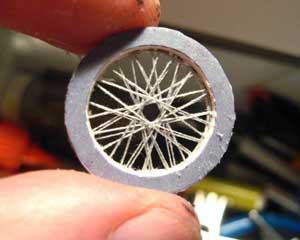

Now we start threading our wheel. For thread we suggest you use the Silver Metallic thread that you can pick up at fabric shop. |

|

We now take the thread and start looping it around the ring template in a pointed "V" shape. We start at the pointed end of the "V". |

|

After you have completed the "V" you simply turn the wheel and start another "V" point on the next notch over. |

|

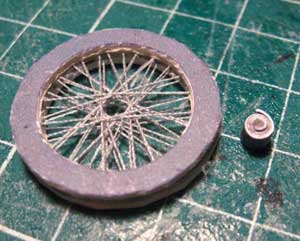

After that you can build up the template on both sides by adding thicknesses of cardboard until you are happy with the thickness of the resulting tires.You can then sand them round if you have the patience for that, or if you have a Dremel. Norman had neither. |

Time to make the hub of the wheel. For that we make a small roll from paper, about as wide as the tire is thick and with a diameter just slightly bigger than the whole in the middle of the spokes. The dimensions aren't critical as long as it looks good. |

|

Keep in mind though that the width of the hub will determine the tension of the spokes and the wider the hub will be, the more it will spread the spokes apart with a resulting increase in tension and a possible warping of the wheel.

This has happened to me but I was still able to straighten it out. |

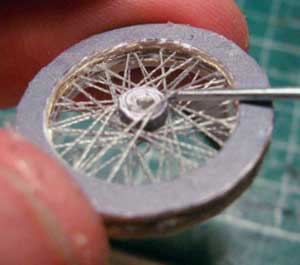

The next step is to wiggle the hub roll through the hole in the middle of the spokes. Since the hub is a little wider than the hole, it won't go through the hole on the other side but will push it outward. And that's exactly what we want. |

|

As soon as the hub sits *IN* the hole on one side and has caught the spokes on the other side, glue it down on that other side where it can't push through. |

|

On the working side we still have to lift the spokes over the end of the hub that sticks out, just like granny used to do when knitting. |

|

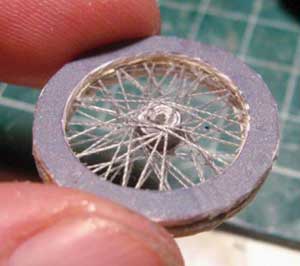

We want the hub to end up wedged in between the two layers of threads.That's what will create the tension and that is where we glue the hub to the spokes to make sure it stays where it is. Once you've got that done, you're finished! |

|

Here is a nice collection of some of Bob's finished spoke wheels... and a couple store bought at the bottom :) |